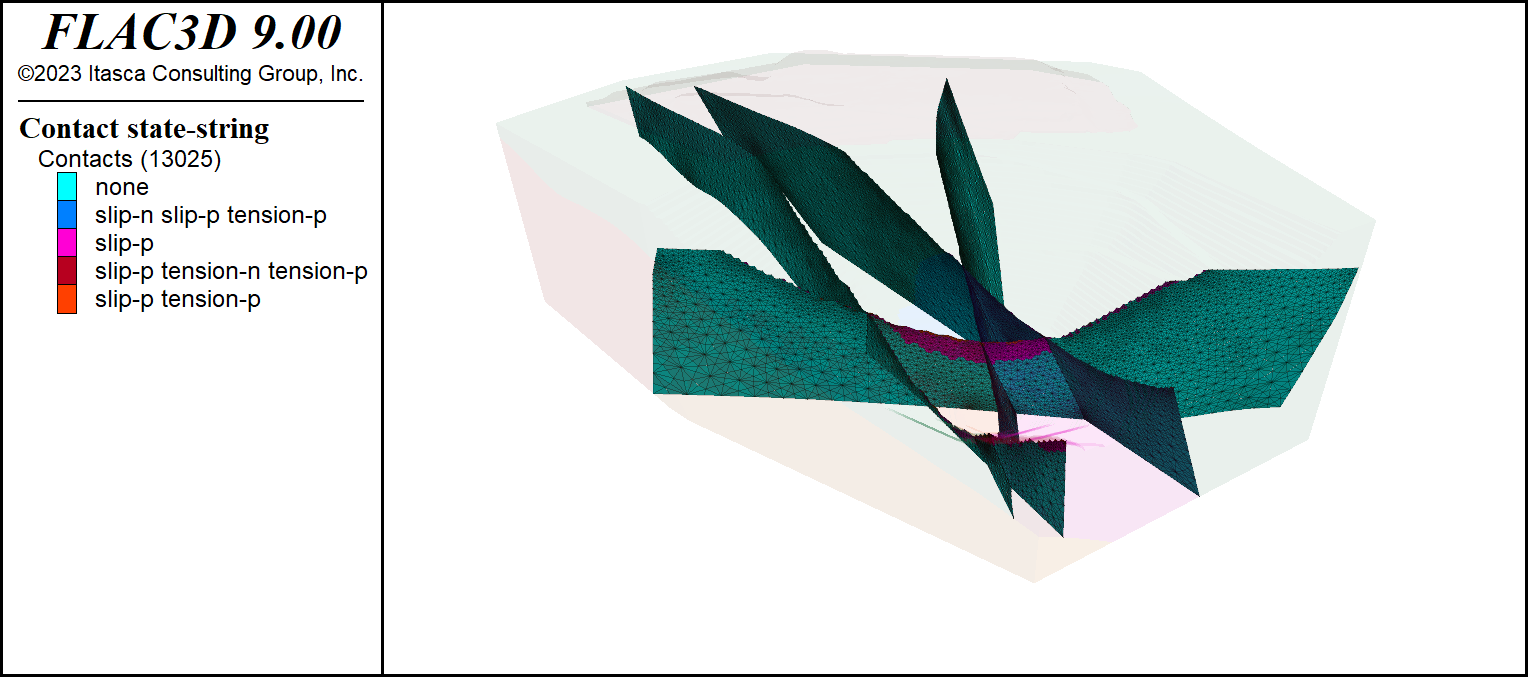

Similar to 3DEC and PFC joints, Zone Joints are an alternative to Interfaces and better represent multiple intersecting joints, faults or discontinuities in small-strain FLAC3D models. The advantage of Zone Joints is that they are two-sided, so the order in which they are created does not affect the results, and forces/displacements at the intersections are more accurate. Contacts are created between separate Zone Joints, defining a two-sided, internal surface that forces can be transmitted across. Mohr-Coulomb is the default joint behavior, but all built-in contact models can be used.

Zone joints also use an incremental formulation for normal stress thereby resolving some Interface related penetration issues. Although FLAC3D does not support any joint cutting functionality, Griddle generated FLAC3D grids include external/interval face groups representing discontinuities. 3DEC generated model zones, joints, and groups can also be easily converted to FLAC3D grids using the new block to-flac3d command.

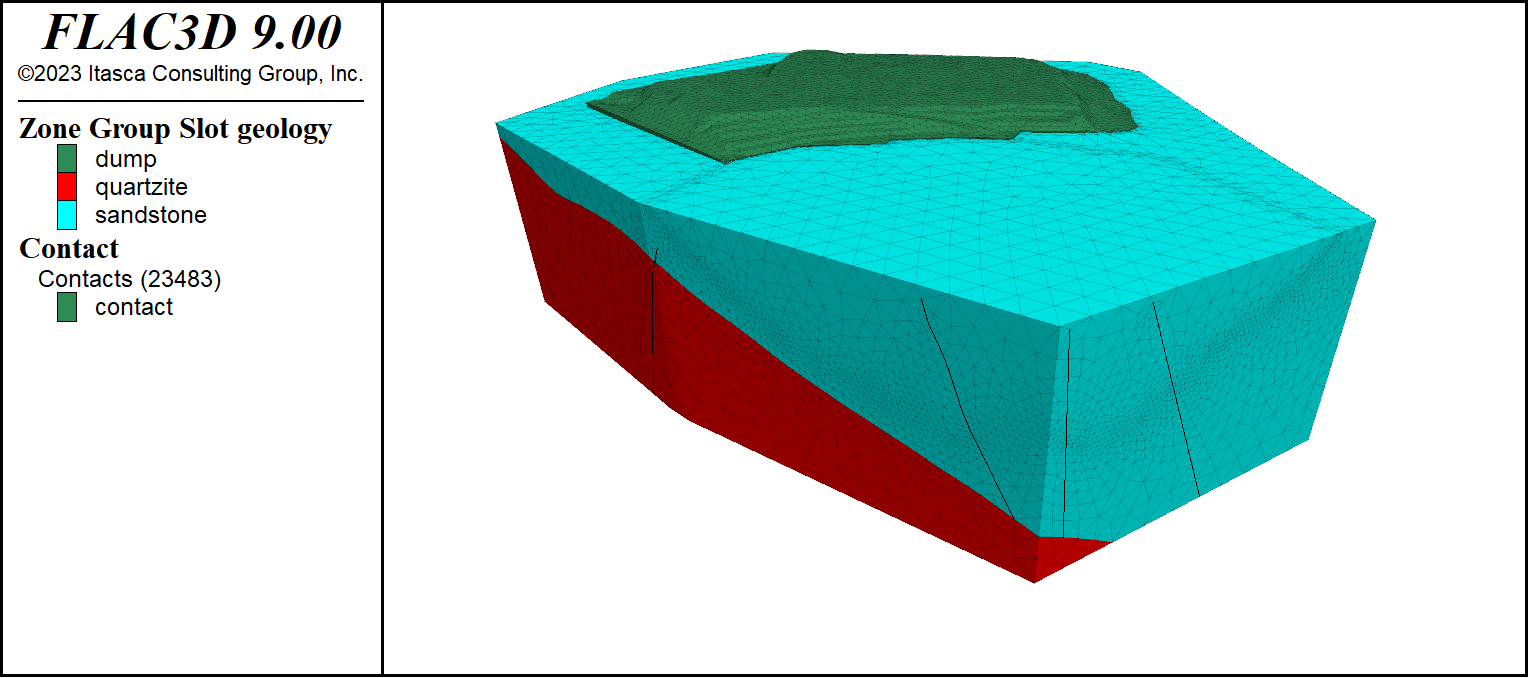

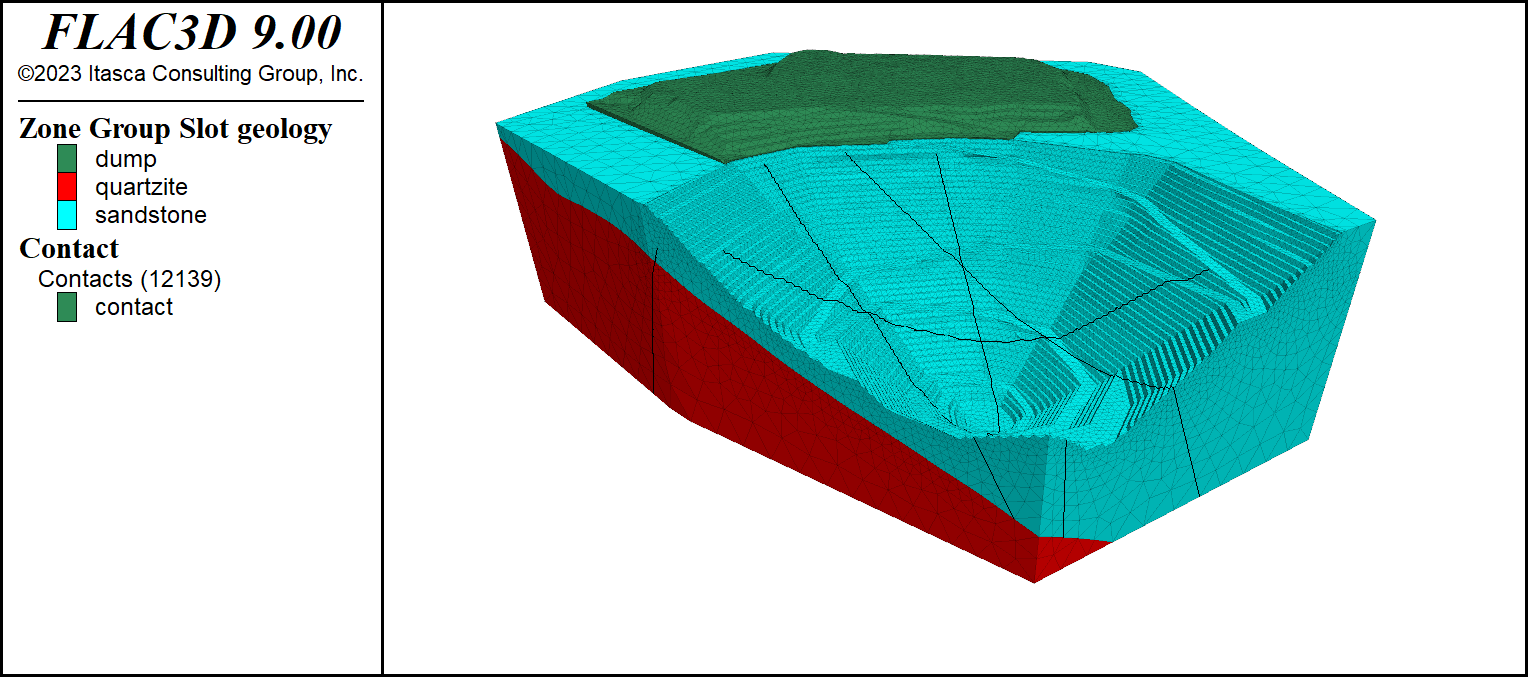

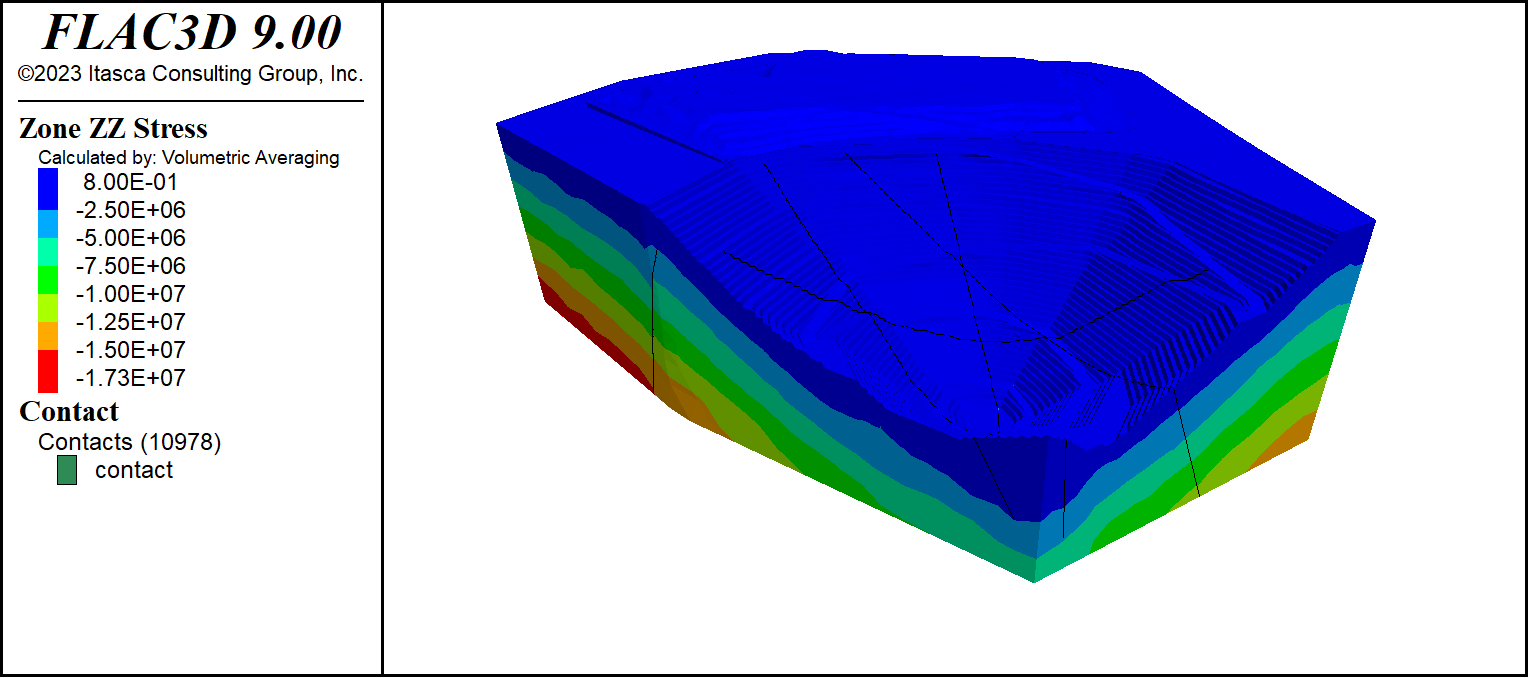

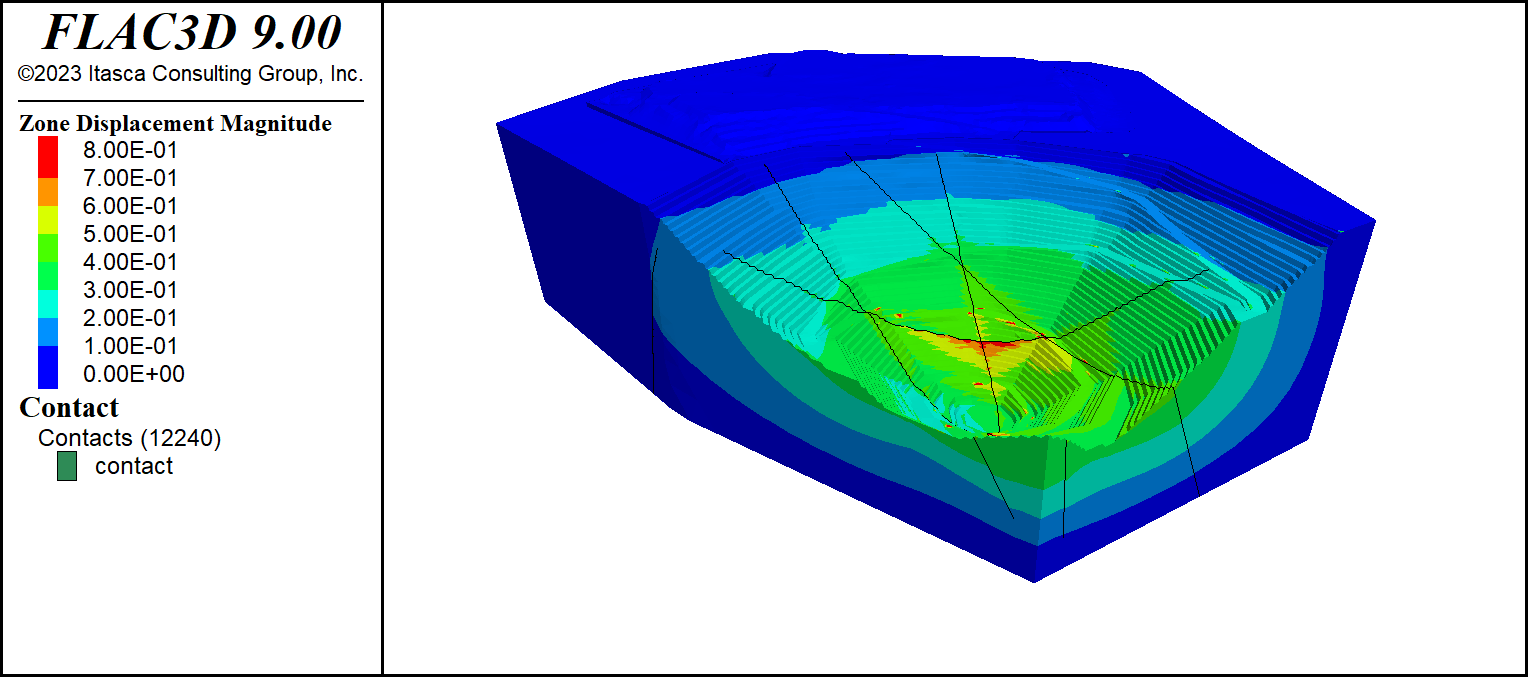

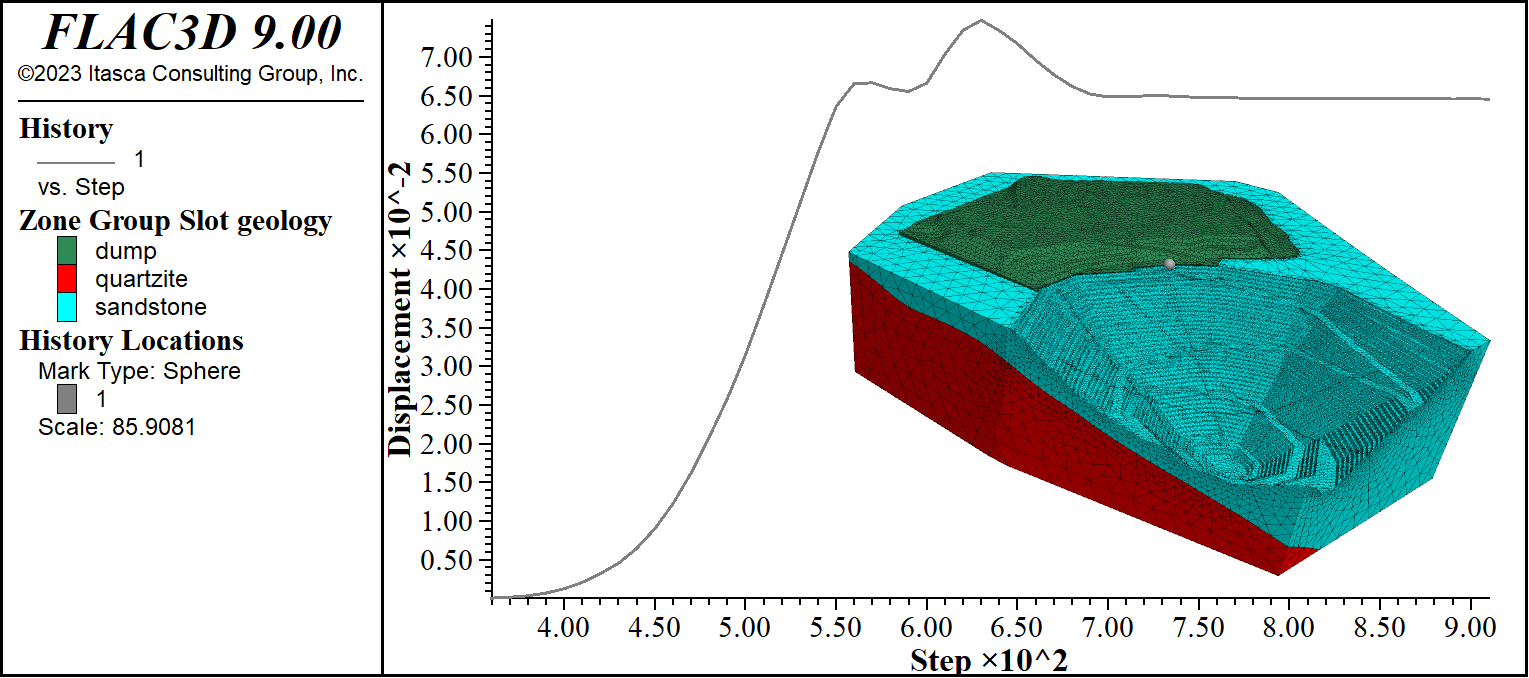

OPEN PIT EXAMPLE

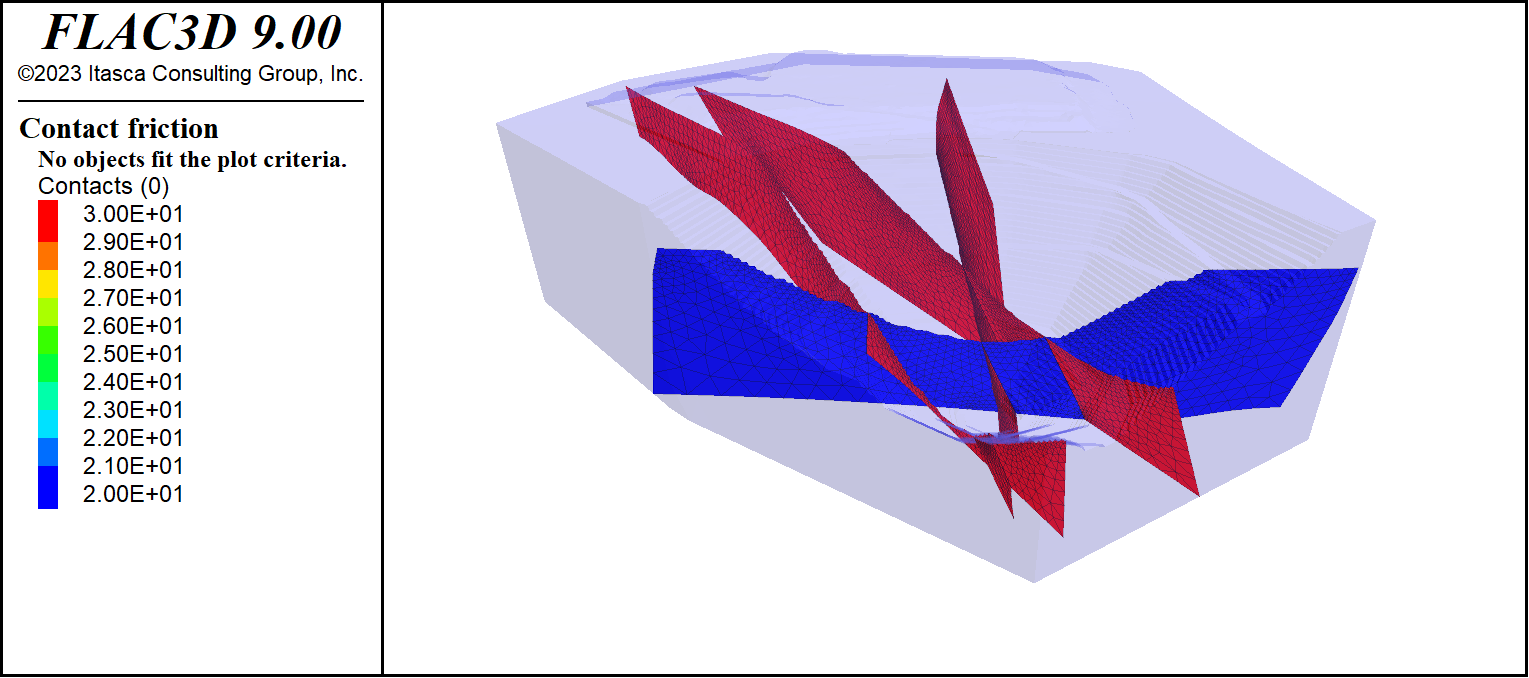

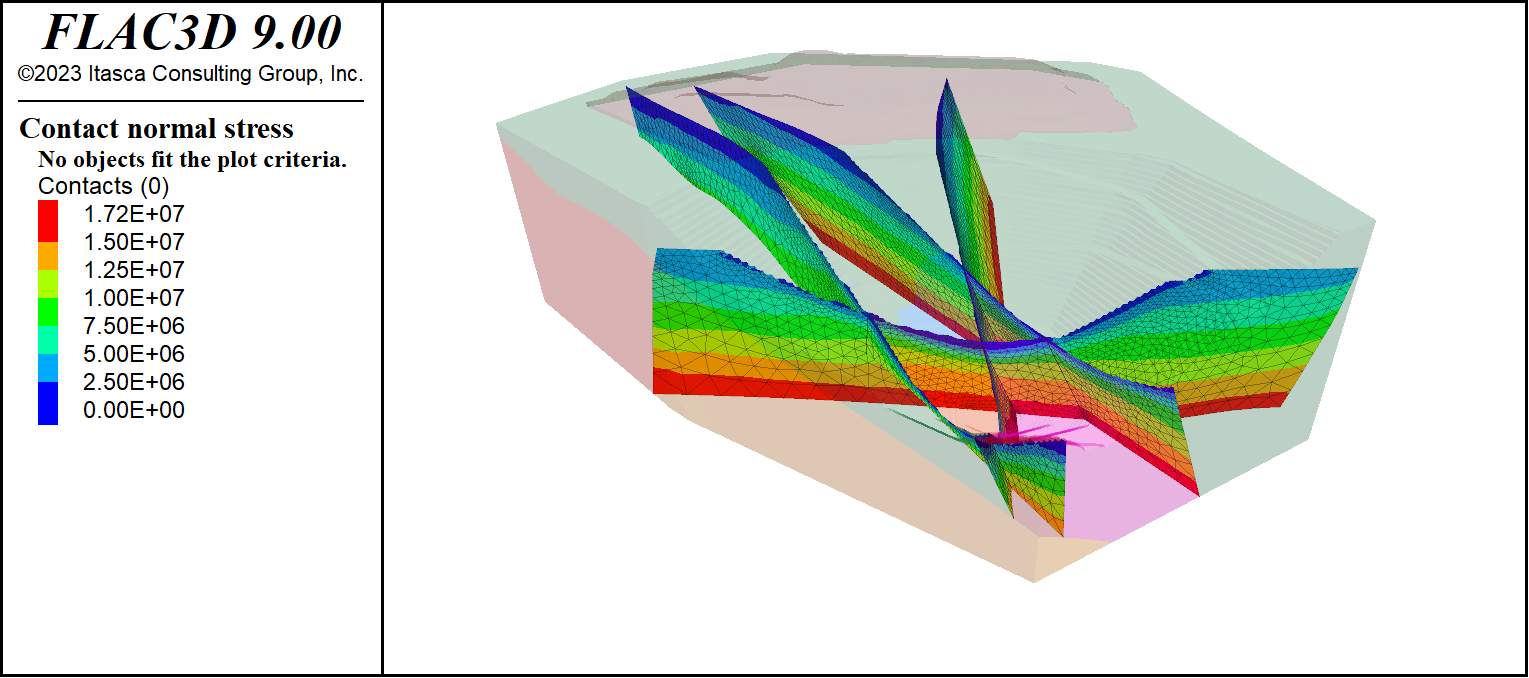

Below you can see a series of plots for a 500-meter deep open pit with several large faults. The model mesh was generated using Griddle. The site geology includes several rock lithologies and there is a nearby waste dump. One critical fault has a lower friction angle than the others. This example demonstrates the main considerations for modeling faults in FLAC3D and will be available shortly in the FLAC3D 9 documentation.