ITASCA offers advanced, first-hand knowledge of mining challenges around the globe and a collective pool of expertise covering a wide range of mine operations, from hard to soft rock mining using both open pit and underground techniques. The company understands the unique geomechanics, hydrologic, and microseismic problems associated with surface and underground mines and the logistical constraints that are encountered in solving them, including:

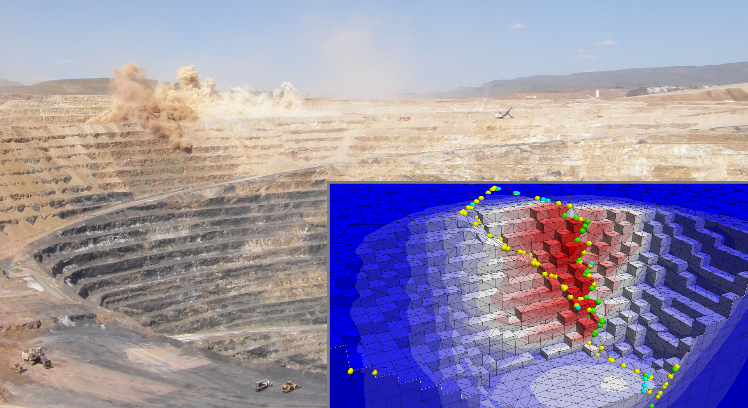

- Slope stability

- Subsidence/mining-induced ground deformations

- Mine dewatering

- Ground control

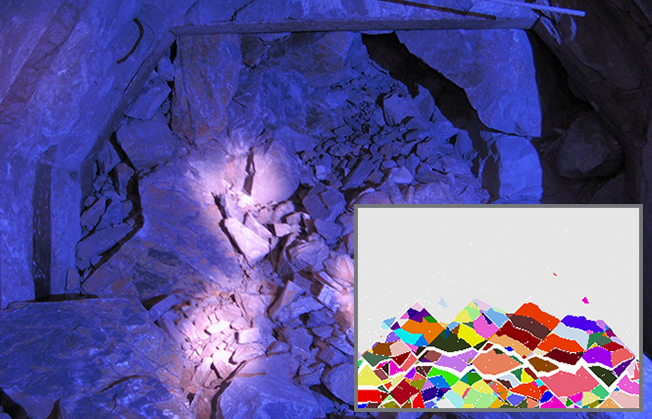

- Excavation stability

- Pit and underground blasting efficiency

- Caveability

- Recovery and dilution

- Fragmentation

- Backfill design

- Tunneling design

- Tailings dams design and stability

- Solution mining and caverns

- Microseismic design, processing and interpretation

- Water-quality impacts

- Heap leach performance optimization

- Water supply

- Water-resource impacts

- Fate and transport analysis of chemicals in soil and groundwater

- Support of permits and due diligence auditing

- Hydrogeologic characterization

- Mine feasibility evaluation

- Pit lake chemistry

- Mining methods selection, excavation geometries and sequences

- Design, installation and monitoring of instrumentation systems

While Itasca utilizes a wide variety of engineering analysis tools, including analytical solutions and empirical charts where appropriate, expert use of 2D and 3D numerical models is usually of critical value to clients. Mine-scale models represent the rock mass from the ground surface to depth below the orebody and would include the lithology and geologic structure, utilizing the existing geotechnical model as input. The model would apply in-situ stresses as measured and simulate the sequential extraction of the orebody in many mining steps. At each step, displacements, strains, and the stress state in the surrounding rock is computed and the yielding or failure state of the rock mass determined. Thus, as a function of extraction sequence (and extraction ratio), the stability of any slopes or pillars and associated deformations can be estimated. To examine the stability of critical infrastructure (crusher station, ventilation raise, haulage way), a number smaller-scale numerical models may be developed.