Stability Analysis of Underground Powerhouse Cavern Group of Jingning Pumped Storage Power

Project Background

Jingning Pumped Storage Power Station is located in Shawan Town, Jingning Autonomous County of She nationality, Zhejiang Province.

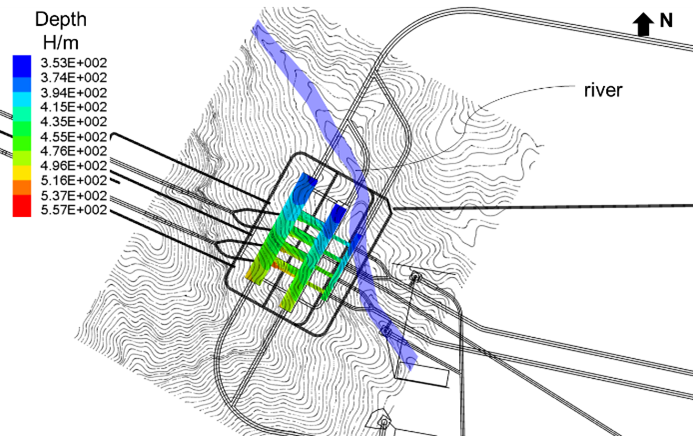

The underground powerhouse cavern group has a depth of approximately 450–550 m and mainly consists of the main and auxiliary powerhouse cavern, the main transformer cavern, and the tailgate caverns, which are arranged in parallel. In general, the scale of the underground cavern group is relatively large: (1) the maximum dimensions of the main and auxiliary powerhouse are 176.0 m long, 57.5 m high, and 26.0 m wide; (2) the main transformer cavern is 178.0 m long, 20.0 m high, and 23.0 m wide; and (3) the tailgate chamber is 110.0 m long, 21.7 m high, and 8.0 m wide. The layout of the Jingning underground powerhouse cavern group is shown in Figure 1.

In the feasibility study, the following critical concerns should be studied by performing numerical simulations: (1) the rationality of the layout of the underground powerhouse caverns; (2) stability analysis and support design of the rock mass surrounding the underground powerhouse cavern group; and (3) the block stability controlled by discontinuity fractures of the underground powerhouse cavern group.

Model Description

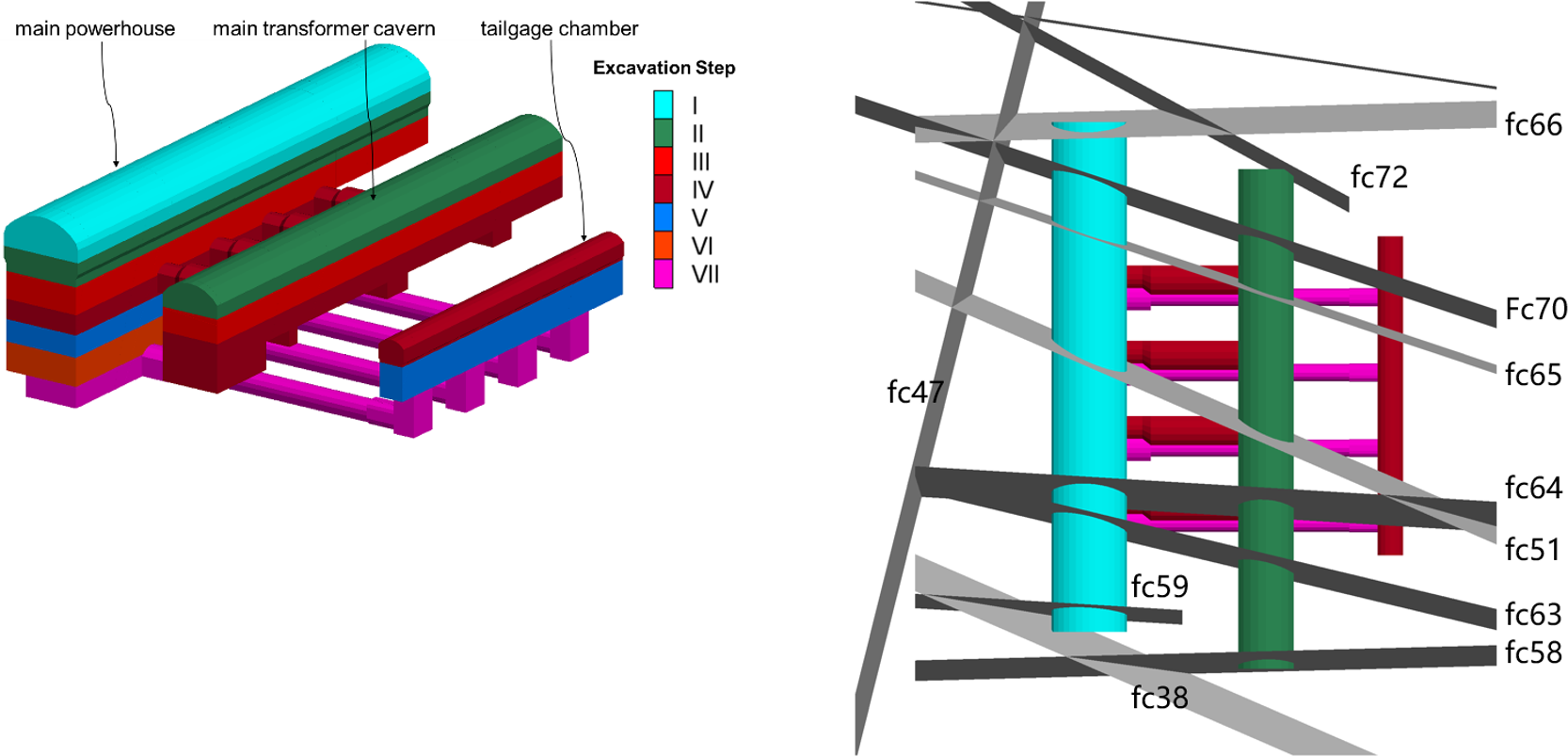

A 3D stability analysis model was constructed using 3DEC. Three main factors were required in the 3D model: (1) To ensure the reasonability of the stability analysis, the initial geostress of the rock mass was obtained by performing a back-analysis based on hydro-fracture field stress test results. (2) The surrounding rock mass of the underground powerhouse cavern group is mainly classified as Class III ~ II. According to China’s industry code, the mechanical behavior of the rock mass was simulated with the Mohr-Coulomb constitutive model, whose parameters were analyzed by the Hoek-Brown approach. (3) Besides large geological structures, three sets of fractures observed in the field were also simulated to perform a block stability analysis. The excavation of the underground powerhouse cavern group was simulated in seven steps.

Results

In the feasibility study, the models were used for the prediction of stress, deformation distributions, etc., around the underground powerhouse cavern group during different excavation stages. The model results indicate that:

- The maximum principal stress, σ1, of the rock mass during excavation periods is overall less than 30 MPa. Considering the ratio of σ1 to UCS of the rock mass is no more than 0.45, the risk of stress-induced damage may not be a critical concern in this project.

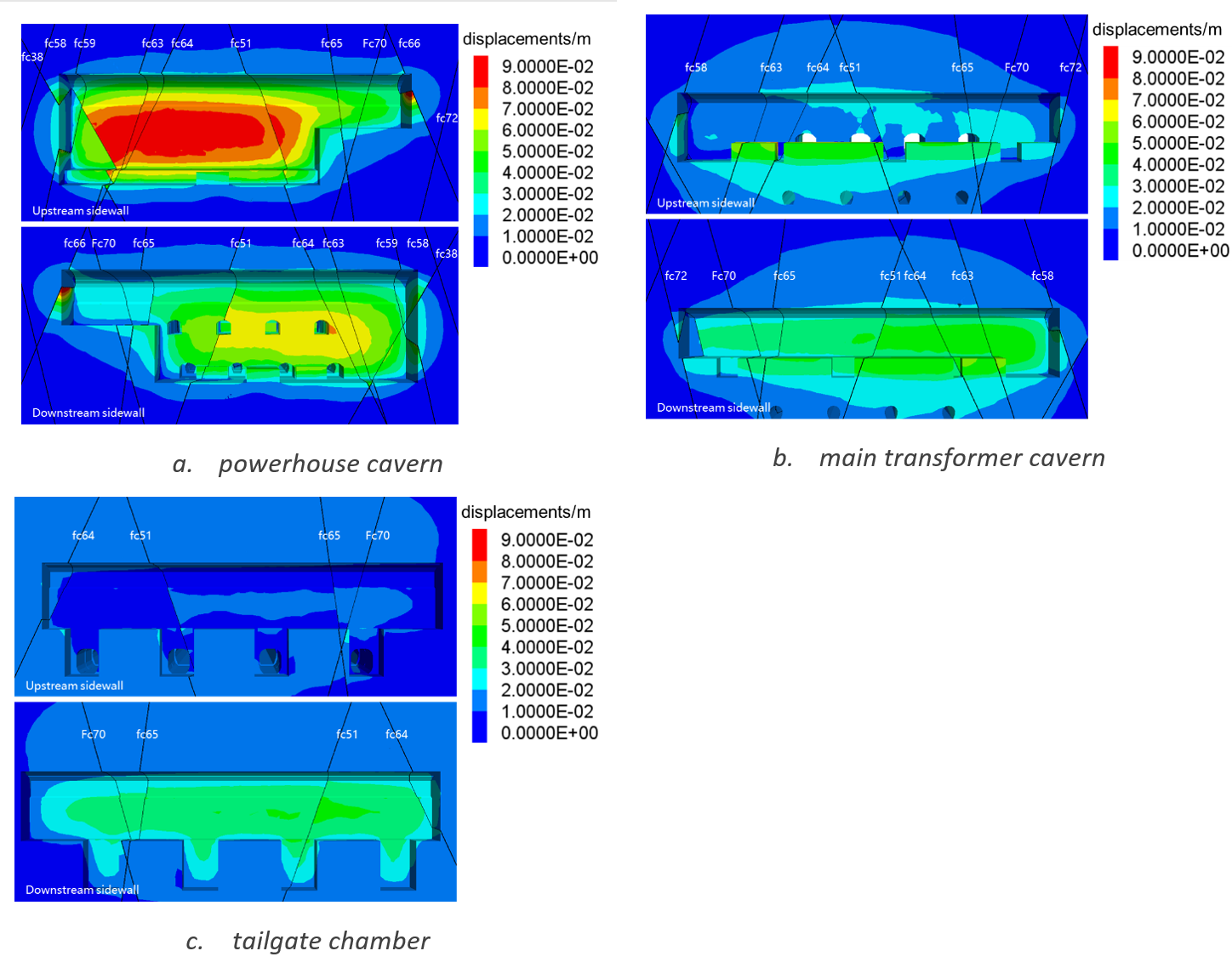

- The displacement distributions of the rock mass around each infrastructure at the final stage is shown in Figure 3, and the maximum displacement close to 90 mm was observed at the upstream wall of the main powerhouse.

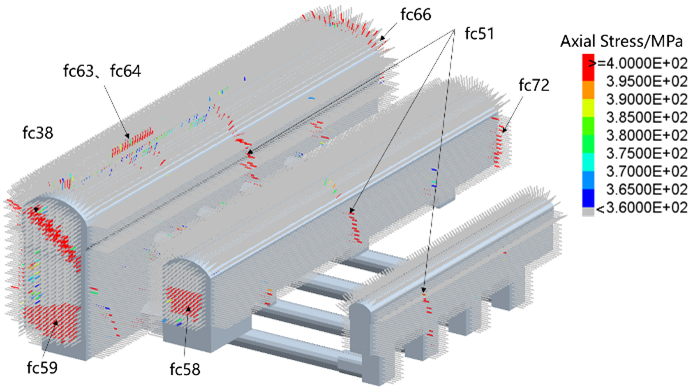

- The axial stress of rockbolts at the final excavation stage is shown in Figure 4, which indicates the axial stress of rockbolts at most of the large faults will exceed the design strength capacity of 400 MPa. Therefore, besides the systematic support approach, additional support measures such as cables should be randomly introduced at these locations to ensure the stability of the rock mass.

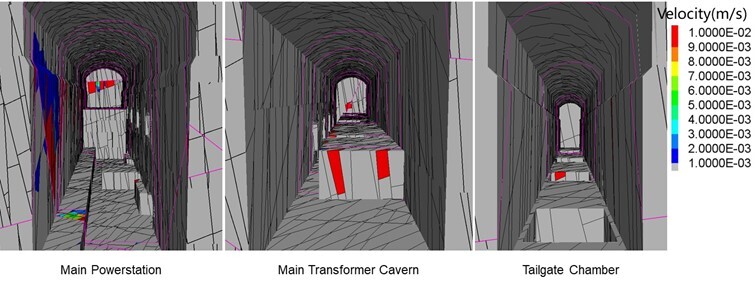

In addition to large geological structures, random joint sets were also considered in the model to assess the stability of rock blocks by performing strength reduction analysis. By gradually reducing the strength of faults and joints with a given ratio to initial strength, the mechanical response such as displacement, velocity, etc., were investigated to reveal the location and scale of potential falling rock blocks around underground caverns.

When the strength of faults and joints were reduced by a factor of 1.5, rock blocks, whose velocity cannot converge, were observed in the rock mass around the underground caverns, as shown in Figure 5.

Summary

The 3D discrete model was constructed using 3DEC to represent the underground cavern group, geological units and major structures or random joints, initial geostress state and rock mass properties. Consequently, the model reasonably simulates the stability of the rock mass and the rationality of support measures is also verified.

References

HydroChina Itasca R&D Center. (2022). “Stability Analysis of Rock Mass of Underground Powerhouse Cavern Group for Jinning Pumped Storage Power Station Project,” Report to HDEC, HIC_JN_ 01/2022 (Oct).